Description

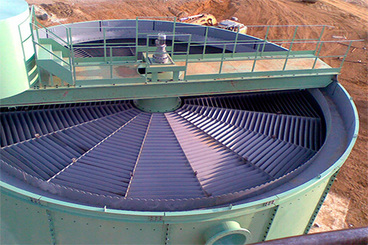

Design, development and supply of processing plants for rock, minerals and industrial waste. Complete solutions using wet and dry methods, incorporating in-house and third-party technologies suited to the specific requirements of each process.

We specialise in designing, developing and supplying complete facilities for applications such as sand production for glass-making, sand and kaolin production for the ceramics industry, the treatment of tailings, the production of dry mortar sands, the production of aggregates for concrete, the treatment of contaminated soil, etc.

Our broad experience in the design and building of facilities enables us to develop solutions tailored to the needs of each individual customer, and to tackle end-to-end projects with expertise and skill.

Working with customers to assess the characteristics of the raw materials to be processed, the end-product specifications required, output and storage needs for those products and the availability of services, TH draws up processes that are optimal in both technical and financial terms.

Our broad expertise and wide-ranging collaborations with other firms enable us to select and size the technologies best suited to each application, so as to ensure the best possible performance at each facility.

As process engineering specialists, we and our collaborating firms handle all the tasks that make up a global project: basic design, detail engineering, equipment construction, installation and commissioning.

At TH our distinctive approach is to take an overall view of the industrial projects that we handle, and to take on board our customers' goals as our own.

Characteristics

Incorporation of the in-house and third-party technologies best suited to each operation at each stage of the process.

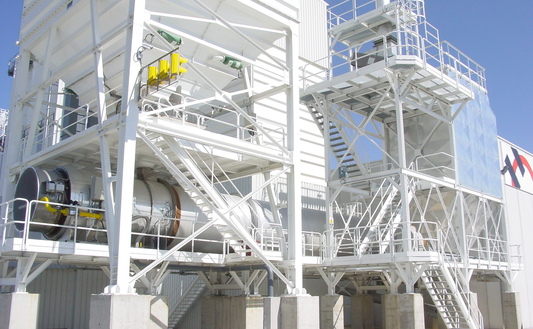

Vertical implementation of facilities wherever possible so as to minimise transportation requirements between process operations.

Large platforms and access areas to facilitate the maintenance and supervision of machinery.

Building of structures out of bolted steel sections.

Running of connecting conduits and pipes in different materials and finishes to suit each application and process.

Building of hoppers, tanks, guttering, etc. with wear-resistant claddings if the application so requires.

MCC centralised or localised by stages or operations. Single control and monitoring centre using HMI and/or SCADA.

Design and construction of equipment, structures, piping, tanks, electrical panels, electrical installations, etc. to EN ISO or EN IEC standards, and to other standards on request.

Broad ability to adapt to specific customer requirements.

Mining

Mining Industrial Minerals

Industrial Minerals Aggregates

Aggregates Enviro

Enviro Products

Products Services

Services