Description

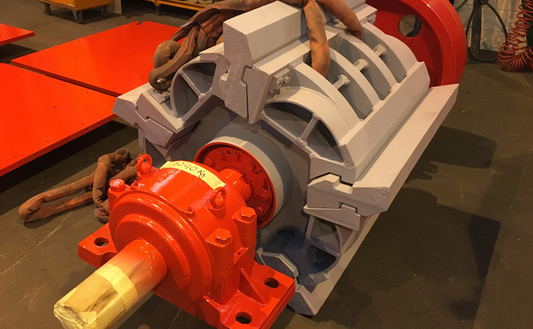

The ML impact crusher stands out for its powerful rotor, for the quality of the special anti-wear materials used to build it and for the exclusive design of its crushing chamber. This perfect combination joins with its high output and reduction coefficient to make it the ideal primary, secondary or even tertiary crushing processes for a range of applications such as the crushing of aggregates, industrial minerals and recycling products.

ML impact crusher comes in various configurations (MLA, MLS, MLR and ML) to ensure the right crushing solution for each application. Each configuration also comes in different sizes to suit different production requirements.

Anti-wear materials are used for critical elements such as the manganese steel blow bars. The sturdiness of the frame and the incorporation of a fast blow bar and shell replacement system reduce operating costs and facilitate maintenance work.

Rotor speed can be adapted to suit the material processed and the end product produced, thus maximising output and reduction levels.

ML impact crushers have inspection doors to enhance operator safety and reduce the number and duration of stoppages in production. Some models also have an innovative hydraulic unblocking system.

Characteristics

A robustly designed impact crusher with a welded, ribbed steel frame and rotor.

Hydraulic opening and fast shell change system.

Hydraulic unblocking system on some models.

Optional grating system on some models.

Industrial Minerals

Industrial Minerals Aggregates

Aggregates Enviro

Enviro Products

Products Services

Services