Description

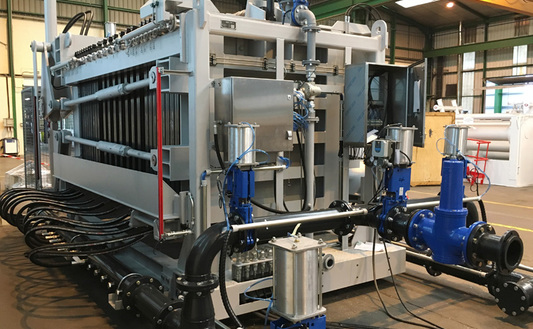

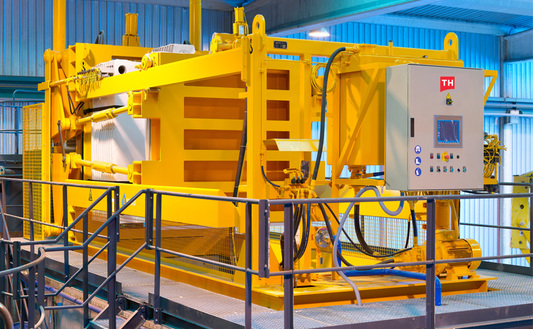

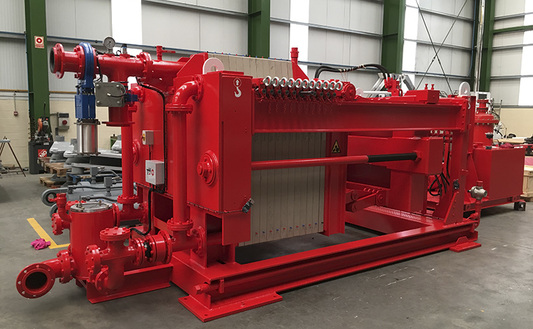

APN - APNH filter presses can be fitted with plates of different sizes, materials (polypropylene, steel etc.) and configurations (chamber or membrane.) Together with a range of filter plate pack opening solutions, their versatility means that they can be adapted to provide the best solution for each process, being recommended APN filter presses for medium capacity filtration processes and APNH filter press range for high capacity filtration processes.

TH filter press design is based on mechanical simplicity and robustness which makes for easier operation and maintenance of equipment. It also ensures lower operating expenses (OPEX) compared to other solutions in the market.

APN - APNH filter presses have robust frames with the filter package supported on a lateral beam. A filter package opening/closing system with a full pull mechanism, ensures that no horizontal force is applied to the frame or the supporting structures of the equipment.

TH's exclusive filter plates with their high strength cores and perimeter seals for optimum sealing are the perfect match for APN - APNH filter presses in the toughest applications. Their advanced design and modular configuration means that our filters can work with abrasive materials and corrosive media, ensuring high output levels at the lowest possible cost per tonne.

Characteristics

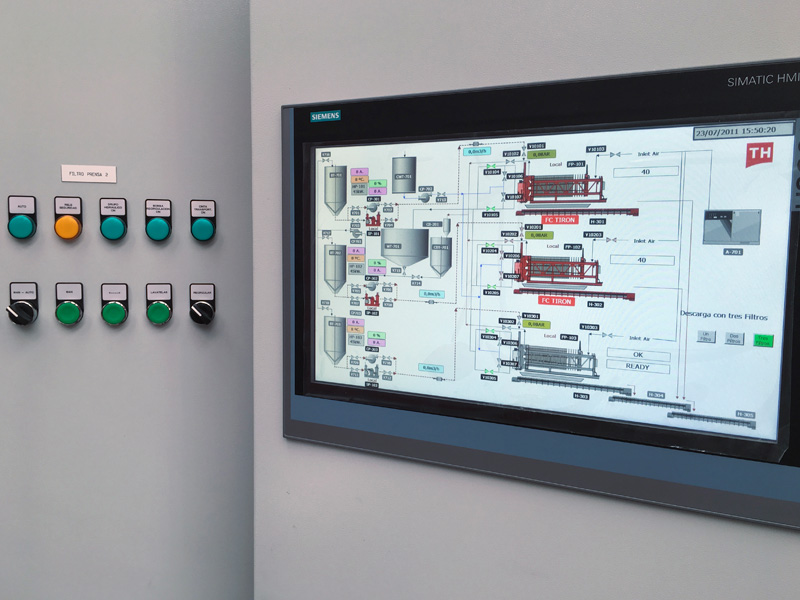

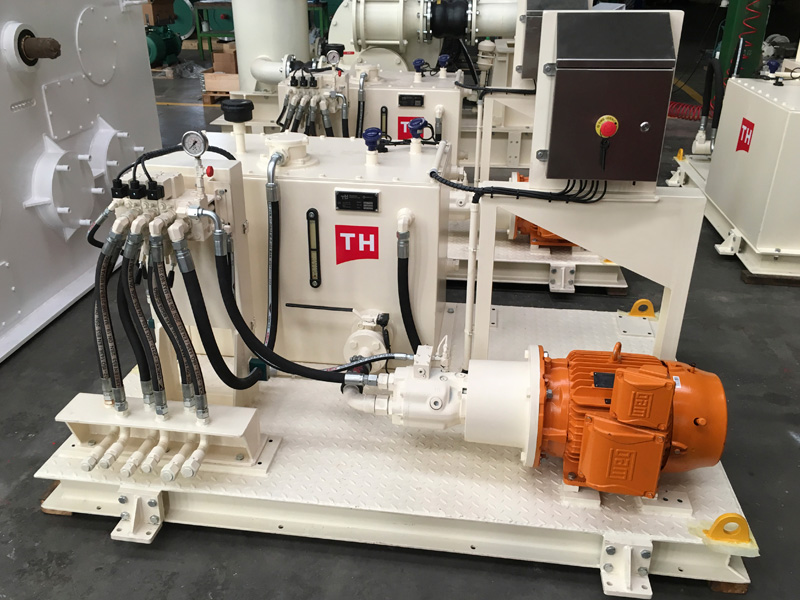

A compact unit with a fully automatic pulling opening/closing mechanism that uses high performance hydraulic cylinders.

A system for transmitting movement on the mobile plate that optimises the distribution of stresses.

Top feeding to ensure the best cake distribution and an advanced cake unloading system to minimise downtime.

Multiple chamber or membrane filter package configurations with polypropylene plates or high performance TH plates with steel core.

Exclusive high output filter press models for mining.

A wide range of process options (cake drying, cake washing, drip trays, filter cloths, special coatings etc.)

Mining

Mining Industrial Minerals

Industrial Minerals Aggregates

Aggregates Enviro

Enviro Products

Products Services

Services